Minimize Risk, Maximize Assurance

Increasing quality while reducing labor and material risks through our in-house manufacturing, prefabrication, and distribution capabilities.

The LINK: our own 208,000-square-foot manufacturing, prefabrication, and distribution facility allows us to streamline the supply chain, increase agility, and monitor and manage material costs and lead times.

UL891 Switchboards

Power and Reliability, Without Delay

To take control of uncertainty and ensure our partners’ success, we’ve developed our Specialized Manufacturing Division to build our own custom switchboards. Leveraging our years of expertise in Electrical Design-Build, we’re delivering critical power, reliably.

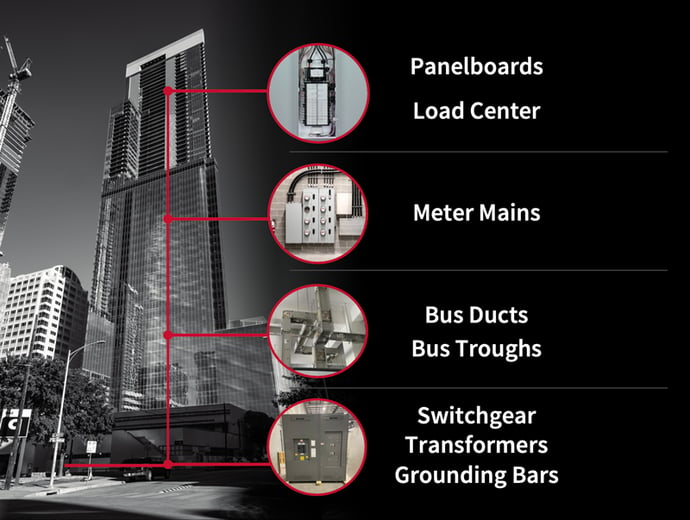

Additional Products

Critical Power Solutions at the Ready

We're supplying products across the critical power chain, with UL-certified switchboards, busways, panel boards, transformers, LFDs, enclosures, and more. Many in inventory, all with shorter lead times than the industry standard.

Check out our linecard of products

Learn more and order here

Our GearedUp Program

Designed & Validated for Seamless Install

Each of our switchboards has its installation Super/Foreman travel to our LINK manufacturing facility to validate their boards—making adjustments where necessary to ensure a seamless install without jobsite surprises. Hear from a PM & Distribution team who just finished evaluating their switchboards, just 6 weeks after their submittal.

Controlled Fabrication

Unit-Ready Delivery

Our 55,000-square-foot dedicated prefabrication space allows our skilled tradespeople to craft a range of units. Prefab drives the most value when:

- Labor costs are high

- Unit layouts are substantially repeated

- Jobsite space is scarce

Prefab Case Study

Efficiency and Quality, Delivered

From LINK to Seattle, hear a Super's viewpoint on our Prefabrication capabilities and its added value.

Watch VideoAdding Assurance to Your Projects

-

Improved Quality

Improved Quality

Improved QualityValidated, Tested, and Certified to Control Quality

We physically evaluate and test each product for quality assurance and proactive resolution when needed. Items are coded, photographed, filed, and then stored in a protected environment until needed on the jobsite. Our fabrication and manufacturing processes have multiple layers of testing, evaluation, and QC. Our products are certified by UL—the nation's leading safety testing and evaluation agency.

-

Increased Efficiency

Increased Efficiency

Increased EfficiencyFaster to Jobsite, Quicker to Market

Build materials and prefabbed items are shipped to jobsites as needed, crated by floor and packaged by unit to avoid any miscommunications or delays. We also leverage our own fleet to deliver your products to site with the care of our own employees, without third-party stops along the way. Our tracking systems, meticulous processes, and centralized distribution from the LINK have driven our on-time delivery rate and accuracy north of 99%.

-

Guaranteed Consistency

Guaranteed Consistency

Guaranteed ConsistencyOne Source with a Common, Specialized Manufacturing Delivery

With one central hub for prefabrication, manufacturing, sorting, kitting, and inventory management, we can ensure uniformity, excellence, and consistency in the delivery of our product to your project. We've developed best practices and rigorous training to ensure we deliver on quality, continuity, and durability.

-

ORGANIZED PRODUCTIVITY

ORGANIZED PRODUCTIVITY

ORGANIZED PRODUCTIVITYReducing Risk and Chaos on Jobsites

We prioritize both our people and our partners' safety on job sites by providing a controlled and clean environment for prefabrication and manufacturing. By producing at the LINK and delivering products to the jobsite when needed, we reduce risk while adding installation speed and safety in the field.

Improved Quality

Validated, Tested, and Certified to Control Quality

We physically evaluate and test each product for quality assurance and proactive resolution when needed. Items are coded, photographed, filed, and then stored in a protected environment until needed on the jobsite. Our fabrication and manufacturing processes have multiple layers of testing, evaluation, and QC. Our products are certified by UL—the nation's leading safety testing and evaluation agency.

Increased Efficiency

Faster to Jobsite, Quicker to Market

Build materials and prefabbed items are shipped to jobsites as needed, crated by floor and packaged by unit to avoid any miscommunications or delays. We also leverage our own fleet to deliver your products to site with the care of our own employees, without third-party stops along the way. Our tracking systems, meticulous processes, and centralized distribution from the LINK have driven our on-time delivery rate and accuracy north of 99%.

Guaranteed Consistency

One Source with a Common, Specialized Manufacturing Delivery

With one central hub for prefabrication, manufacturing, sorting, kitting, and inventory management, we can ensure uniformity, excellence, and consistency in the delivery of our product to your project. We've developed best practices and rigorous training to ensure we deliver on quality, continuity, and durability.

ORGANIZED PRODUCTIVITY

Reducing Risk and Chaos on Jobsites

We prioritize both our people and our partners' safety on job sites by providing a controlled and clean environment for prefabrication and manufacturing. By producing at the LINK and delivering products to the jobsite when needed, we reduce risk while adding installation speed and safety in the field.

Power Design's Fleet

Tracking, Care, and a Handshake on Arrival

No matter where your project is, our commitment to reliability guides every mile. From storage to shipment, we handle your materials with care—packing, kitting, crating, and wrapping with precision. And with a 24/7 tracking and stringent quality assurance, we keep you updated every step of the way. We are designed to deliver, without detours.